Monroe’s Multi-Stage Oil Mist Collector Solves Synthetic Fiber Plant’s Oil Mist Problems

Challenge

A synthetic fiber plant’s manufacturing operations produced a large amount of oil mist. The oil mist consisted of heavy oil droplets, smoke, and sub-micron vapors. The manufacturer required the air to be cleaned of the oil mist and other pollutants before discharge into the atmosphere.

Solution

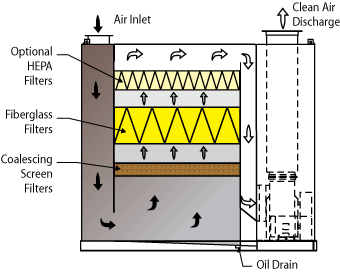

The plant examined various types of oil mist collectors and selected a Monroe Environmental self-contained, four-stage collector to solve the problem. The Multi-Stage Oil Mist Collector had no moving parts in the collection zone.

In the first stage, the larger oil droplets were removed in a drop-out chamber and drained to the sloped bottom. The second stage contained coalescing media that captured the smaller oil droplets. The smallest oil particles were passed through specially constructed fiberglass media filters in the third stage. The fourth stage included high-efficiency fiberglass filters to capture remaining sub-micron particles resulting in air that is clean enough to be discharged to the atmosphere.

Result

The Oil Mist Collector was installed successfully and allowed the plant to effectively clean the polluted air stream. The system operates at 95% efficiency, treating 0.3 micron-sized particles. With no moving parts, the system continuously performs with minimal maintenance.

To know more, please check Monroe Environmental.