Water Pollution Control Equipment

Wastewater treatment is the cleaning and processing of municipal, industrial, and/or agricultural waste and drainage. This water is often highly contaminated with biological waste and chemicals and must be treated before it can use for any other application. Most organic matter and associated wastewater contain hydrocarbons. These emissions are highly regulated, because of their major role in pollution and climate change. Nearly every waste processing plant in the world is required to have some form of pollution control equipment (water and air), which many municipalities see as an unwanted but necessary expense. The goal of treating this waste is to get it clean enough that it can be reused in other applications. Because these streams are organic waste, they contain compounds that when captured, can be incredibly valuable. The pollution control equipment used during this process also produces heat that can be used. This is achieved through a multi-step process.

What is the process of wastewater treatment for revenue generation?

Step 1: Removing large particles (grit) using screens. This is necessary to prevent damage and clogging to the facility’s pumps and equipment. A bar-type screen is generally used to achieve this, and the collected waste is then sent to landfills.

Step 2: Grit removal, using grit chambers. The bar screens remove large debris but do not filter any of the smaller grit and sand out of the influent. This grit can cause damage to the downstream equipment and must be removed. Different types of grit chambers push a flow of water through the top of the chamber, allowing the grit particles to settle on the bottom. The remaining water and organic matter are then ready for the next step in the process.

Step 3: Sludge processing in a digester. Water then flows through the tank at a rate in which the remaining solid organic matter in the influent separates from the water. This collected organic material is called sludge. The sludge, also known as slurry or biomass, is stored in the liquid manure storage area, where feeding liquid material and additional biomass quantities are feed into the system. It is then processed through a heated digester, which uses anaerobic digestion to break down the material. This is referred to as biofiltration. Biofiltration is the process of utilizing natural biological oxidation for the destruction and removal of VOCs, odors, and hydrocarbons. Simply put, biofiltration is the degradation of organic and inorganic substances by microorganisms. The air flows through what is called a packed bed of media, causing the pollutants to transfer into a thin biofilm on the surface of the packed media. The microorganisms are housed in the microfilm and degrade the pollutants. The mix in the digester is always specific to the input materials and must be well mixed and homogenous so that the bacteria and substrates are in close contact. This ensures a high gas yield. The heated digester is the main area of any biomass plant, meaning it can be used to create electricity and biofuel.

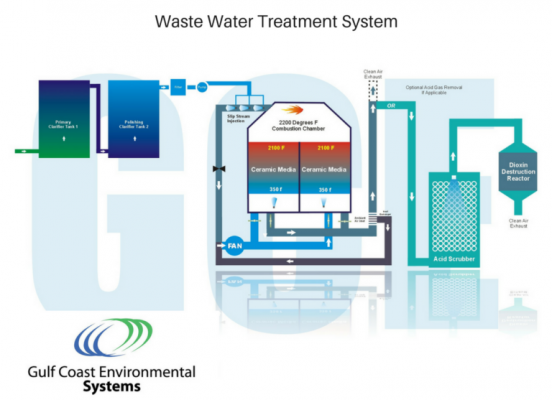

Step 4: Leachate treatment. The reaming liquid is known as leachate. Leachate is defined as water that has percolated through a solid and leached out some of the constituents. This means that after flowing through the tank to separate the sludge, it is contaminated with compounds that must be treated and removed before the water can be returned to the environment. This is achieved using a thermal oxidizer, and in some cases, an acid scrubber.

Step 5: Turning waste gas into RNG. The digester gas, which contains methane, CO2, nitrogen, and hydrogen, among other things, can be converted into pipeline quality RNG. The RNG created by wastewater methane-rich waste gas abatement is incredibly valuable because it can be used interchangeably with natural gas for heat, electricity, and even transportation. With traditional natural gas costing around $4/MMBtu, and RNG costing up to $24/MMBtu, there is an obvious value in this readily available alternative fuel. The process we use begins when pressurized feed gas is led through a series of filtering equipment to remove contaminants which protect the membrane fiber from liquids, certain chemicals, and particulates. Temperature control is critical going into the membrane package. These membranes separate the gas specific rich permeate and lean residue. The separation of permeate and residual gas is driven by the partial pressure difference between the feed gas and permeate gas as well as the advanced polymer material. Additional gas rejection systems are typically required after gas separation, to meet certain final product specifications.

electricity, and even transportation. With traditional natural gas costing around $4/MMBtu, and RNG costing up to $24/MMBtu, there is an obvious value in this readily available alternative fuel. The process we use begins when pressurized feed gas is led through a series of filtering equipment to remove contaminants which protect the membrane fiber from liquids, certain chemicals, and particulates. Temperature control is critical going into the membrane package. These membranes separate the gas specific rich permeate and lean residue. The separation of permeate and residual gas is driven by the partial pressure difference between the feed gas and permeate gas as well as the advanced polymer material. Additional gas rejection systems are typically required after gas separation, to meet certain final product specifications.

According to EPA estimates, this biogas potential is about 1 cubic foot of digester gas per 100 gallons of wastewater. Energy generated at U.S. wastewater treatment plants (WWTPs) could potentially meet 12% of the national electricity demand, according to a study released by the National Association of Clean Water Agencies and the Water Environment Federation. This could spur some production of RNG for vehicle use as well.

- There are currently 40 federal tax incentives to produce, use, or sell RNG in the United States.

- Nearly every state has its own incentives that could potentially be applied, in addition to federal tax acts.

ROI Opportunities:

- Methane Abatement & Beneficial Use

- Methane can be incredibly valuable, as there are several ways to abate it and use it as fuel or an energy source. What most people do not know is that methane can be converted into Renewable Natural Gas, electricity, or heat.

- Heat Recovery

- An oxidizer uses extremely high temperatures as a means of destruction. Heat recovery in oxidizers can be accomplished in two different ways: Extracting heat from the stack or extracting heat directly from the combustion chamber. Dryer exhaust air temperature, solvent concentration, and heat exchanger efficiency determine the oxidizer stack air temperature. As oxidizer efficiency is increased, the stack temperature will decrease. Destruction efficiency requirements determine the combustion chamber temperature. When concentrations rise above the minimum energy required for self-sustaining operation, excess heat is generated in the combustion chamber. This excess heat presents a great opportunity for heat recovery.

- Hydrogen Production

- There are certain abatement processes that result in waste byproducts. In some cases, this byproduct can be repurposed, and even sold. Recent developments between leading worldwide governments are revolving around the desire to create ‘Hydrogen Cities’. This is already occurring in Europe and China. The use of GCES and partner technologies while consuming wastewater creates a large opportunity to turn wastewater into a profit.

- Carbon Trading

- A facility that implements a green energy program is eligible to receive carbon credits. Carbon credits can be sold or traded between participating facilities. One ton of carbon equates to a single carbon credit, which is worth between $11 and $14, depending on the market.

- Tax Incentives

- Countries on nearly every continent are changing their regulations and attempting to incentivize industry to get on board with pollution reduction. These tax breaks and incentives are completely different for each country, and in some cases, even by state and country levels.

- RNG + Green Energy

- RNG stands for renewable natural gas. Renewable natural gas, also known as sustainable natural gas (SNG), or biomethane, is a biogas that can now be used as a pipeline energy source. Natural gas and energy companies can purchase the waste gas from landfill gas abatement, and sell it to their customers. RNG qualifies as an advanced biofuel under the Renewable Fuel Standard.

Funding a wastewater biofuel project:

In addition to new federal tax codes, like45Q, there are 15-states that have their own individual incentives and programs available for biogas projects. Most of these state programs incentivize utilities providers to purchase and use RNG in place of traditional natural gas. Currently, 38-states offer loan programs to facilities interested in starting biogas projects; however, these loans can be complicated and difficult to obtain without proper guidance and support from a biogas expert.

Many of these state and federal programs and tax credits have popped up over the last 3-years, showing a growing interest in RNG projects.

Why choose GCES for your wastewater facility?

Gulf Coast Environmental Systems is a full-service pollution control company. We offer a variety of solutions to customers in the wastewater industry, looking to create a source of revenue from their processes.

Our engineering team has taken a special interest in these types of projects, because of the environmental benefits and revenue-generating opportunities they create for our customers. By designing and custom manufacturing pollution control and gas purification equipment in-house, we are able to provide the best solution for each unique operating condition. Our units have been proven in some of the most challenging environments on earth.

In addition to handling the technical aspect of the project, we are equipped to assist you in every step of commissioning a project like this at your wastewater plant. From finding funding to meeting tax credit requirements, our team is capable and ready to help guide you through it.

To know more, please check the Gulf Coast Environmental System.