Ansys Enables the ITER Organization to Design the World’s Largest Highly Sustainable Nuclear Fusion Power Plant

- Ansys simulation solutions are empowering engineers from 35 countries to build the highly sophisticated ITER fusion energy machine

- ITER engineers use Ansys simulations to enhance electromagnetic (EM) structure design, decrease project risk, reduce physical prototyping and satisfy stringent safety standards

The ITER Organization is collaborating with Ansys (NASDAQ: ANSS) to optimize EM structure design and performance for the ITER, the largest nuclear fusion plant created to affordably deliver clean, net energy and maintain fusion for long durations. Through a new multi-year agreement, Ansys will work with ITER engineers to improve project risk management, streamlining system development, and meeting critical safety requirements.

Fusion power has the potential to be an ideal energy source as it creates little to no emissions or long-lived radioactive waste while generating power around the clock. However, producing a self-sustaining fusion reaction requires an ionized plasma of hydrogen isotopes to be heated to approximately 150 million C°. To sustain this extreme temperature while containing the plasma, the ITER tokamak uses an array of massive superconducting magnets, essentially creating an invisible magnetic cage inside the metal vacuum vessel of the tokamak. ITER engineers leverage Ansys simulation solutions to economically design EM structures.

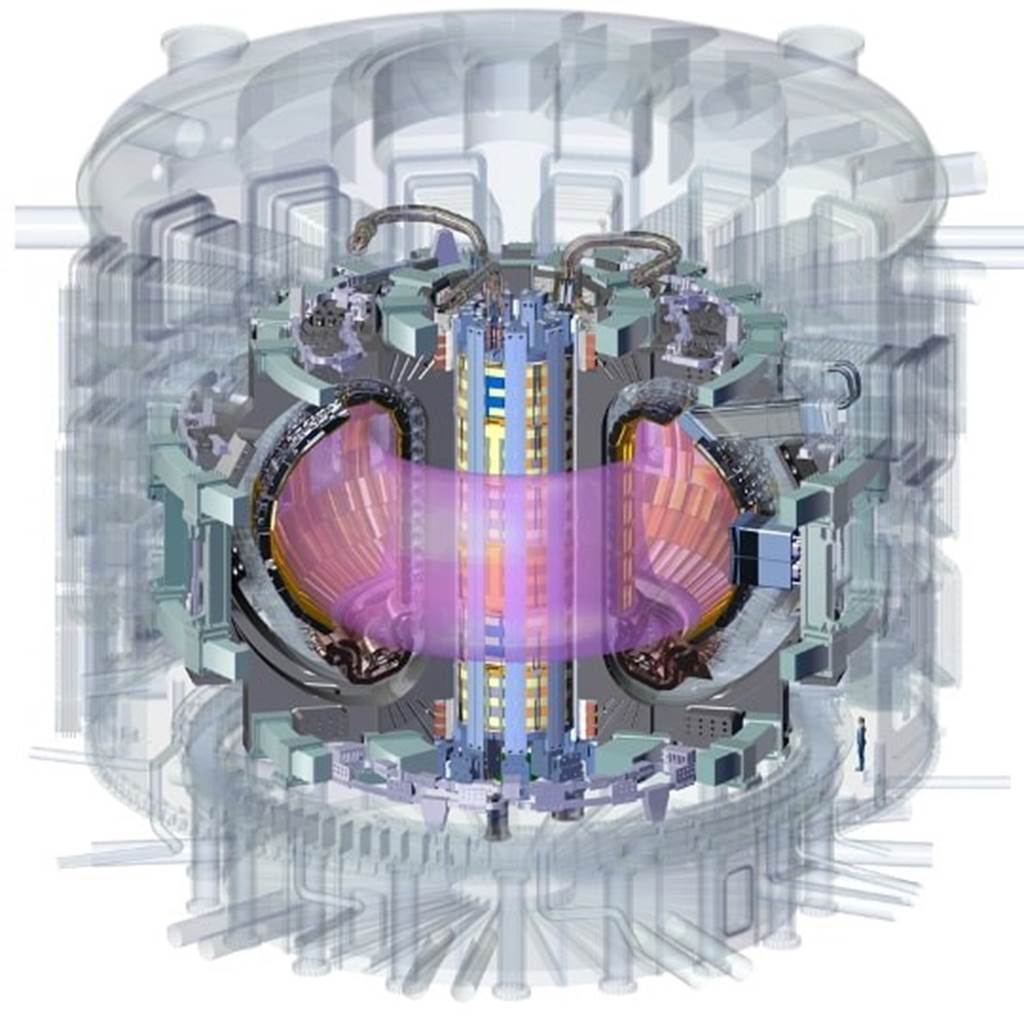

CREDIT © ITER ORGANIZATION, HTTP://WWW.ITER.ORG/

THE CENTRAL SOLENOID FORMS THE SPINE OF THE TOKAMAK MACHINE. ITS FUNCTION IS TO INDUCE THE PLASMA CURRENT AND MAINTAIN IT THROUGHOUT THE DISCHARGE.

From confirming the system design and performance to virtually eliminating the need for physical prototyping, Ansys® Fluent® plays an integral role in validating the extreme cooling system and building a set of documents that ITER engineers will use to ensure the system design is robust and complies with strict project and industry safety standards. Additionally, Ansys® Mechanical™ plays a critical role for the engineers who build the structural supports that secure the ITER’s base.

“Ansys simulation solutions will continue to help our team to satisfy the required safety and accuracy levels for this first-of-a-kind initiative,” said Bernard Bigot, director-general of the ITER Organization. “For ITER to achieve hydrogen fusion at an industrial scale requires unprecedented levels of engineering precision, so it is incredibly important that our simulation software is highly reliable and efficient. Ansys has consistently delivered that capability to us for many years, enabling our team to safely push boundaries, dream bigger and deliver Earth’s biggest fusion reactor.”

“To power, the sun and the stars, light atoms fuse at very high pressures and temperatures. Replicating this process on Earth with ITER will help solve the world’s energy demands, however, engineers must overcome extremely difficult design challenges,” said Prith Banerjee, chief technology officer at Ansys. “Using Ansys simulations, ITER engineers are rapidly building a structurally sound fusion power reactor, drastically reducing the EM structures’ material content and substantially decreasing the plant’s development cost – driving the delivery of clean, sustainable energy for our planet.”

To know more, please check Ansys.