Automation increases material recovery, improves purity and reduces OPEX

Background

In November 2013, Dem-Con Companies, Shakopee, MN, installed a 20 tons per hour single-stream and commercial Material Recovery Facility. The MRF is housed in a 70,000 square foot building and serves the Twin Cities, Greater Minnesota, and surrounding states. The facility was designed and installed by CP Group out of San Diego, CA.

The original MRF equipment includes a CP Drum Feeder, OCCScreen, GlassBreaker Screen, CPScreen, NEWScreen, MSS Aladdin optical sorter, and two IPS Balers. This equipment is still in operation today. At the time of installation, the MRF was highly advanced with all new technology.

Consumer behavior and commodity markets have undergone drastic changes since the original MRF was installed. These changes, among other challenges, created a need for MRF technology improvements.

The Challenge

Multiple challenges led the Dem-Con team to undertake system retrofits:

- Labor shortages

- Commodity prices

- Restrictive end-markets

- Higher quality standards

- Need for improved efficiencies

- Changing consumer behavior

China announced it would stop buying contaminated paper in July 2017. Since this announcement, recycled paper prices decreased rapidly. This has had the most drastic implications on the commodity markets and recycling as a whole in the last decade.

The China Green Fence and National Sword created a demand for improved fiber purity across all markets. These higher paper quality standards could not be met by human sorters alone without incurring severe consequences on operating expenditures and processes.

China’s end-market dissolution, changing consumer behavior, and the lowest unemployment rate since 1969 created the perfect storm. Dem-Con, being a forward-thinking, progressive, and proactive company, looked at their operations and identified that new technology would be imperative.

The Solution

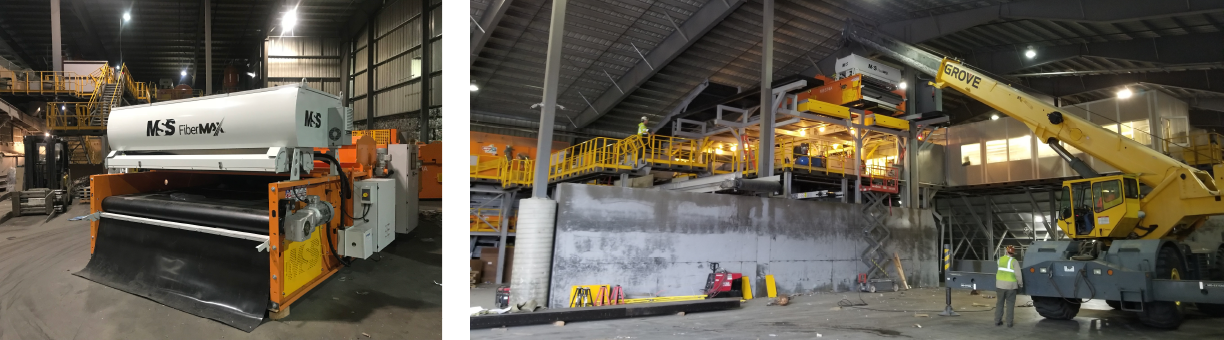

Dem-Con turned to their long time MRF solutions partner, CP Group, to help them with the challenges faced at their MRF. Together, the two companies worked to create a solution. Including MSS optical sorters in the solution was a no-brainer. MSS’s optical sorters solved many challenges, including the need for improved material quality and headcount reduction while processing high tonnages. MSS optical sorters have the highest linear feet of output. They process more volume utilizing the fastest speeds with the widest belts. One MSS CIRRUS® can achieve over 1,000 picks per minute.

Dem-Con and CP worked on several designs. Together, the companies created the solution that would meet Dem-Con’s challenges head-on. At the heart of the system, retrofits are MSS CIRRUS® optical sorters.

To know more, please check CP Group.