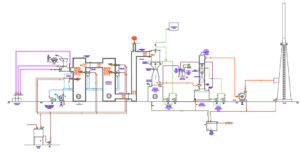

Bio Medical Waste Incinerator

Biomedical Waste means; soiled or blood-soaked bandages, discarded surgical gloves after surgery, IV sets, Urine Bags, Aprons, injections, Syringes, needles, culture dishes, and other glassware, discarded surgical instruments scalpels, sharps, and needles used to give shots or draw blood, cultures, stocks, little blades, swabs used to inoculate cultures, removed body organs like tonsils, appendices, limbs, etc.

Discarding Biomedical Waste is a must as it is one of the dangerous wastes for human life. The Discarding of this type of waste is only possible with the correct incinerator.

Bio-Medical Waste Incinerators are built to meet the need of our customers to improve the pollution in the environment by solid waste and many other waste products.

Incinerator

Waste management has become a major concern worldwide and incineration is now being increasingly used to treat waste that cannot be economically recycled or treated. Incineration is a waste treatment technology that involves the combustion of organic materials. Incineration of waste materials converts waste into Incinerator bottom ash, flue gas, particulates, and heat. The flue gases are cleaned before dispersing in the atmosphere.

Maximus Envirotech offers incineration solutions for a wide range of waste. Our wide experience & exhaustive analysis of the problems helps in providing the right type of solutions for different types of waste. Our incinerators are state-of-the-art units specially designed considering the physical & chemical properties of wastes. Our incinerators are operated by PLC controlled system to ensure failsafe and error-free operation.

Primary Furnace

The waste is charged into this chamber through special waste feeding systems to ensure no exposure of people working near the furnace. The waste is incinerated in this furnace in an oxygen-rich atmosphere. In this furnace, waste is decomposed into volatile gases and carbonaceous material. The furnace is maintained under a negative draft and the low velocity of gases helps in minimizing the carryover of particulate matter. The furnace temperature is closely controlled between 850 Deg C & 900 Deg C using the Auto operation of the Burner. The ashes are removed from the furnace after the operation from Ash Door.

Secondary Furnace

The flue gases coming from the primary furnace containing volatiles & unburnt carbonaceous material are burnt in a second furnace in turbulent conditions. Complete oxidation of the flue gases is ensured by maintaining a temperature above 1000 Deg C & supply of additional Air. A proper residence time is ensured for the destruction of all volatiles.

Salient Features

- Incineration system Built-in with 100% compliance to the requirement of Environmental rules of India as well as International Norms.

- Incineration system with two distinct furnaces i.e primary furnace & secondary furnace with the independent burner system.

- Online monitoring system for monitoring different parameters in flue gases like CO, CO2, HCl, NOx, SO2, and many more as per the requirement.

- Automatic Feeding of Solid & Liquid Waste into the primary Furnace.

- Operates on a variety of Auxiliary Fuels like Furnace Oil, LDO, HSD, Natural Gas.

- Automatic function operation using PLC and SCADA system for optimum operation.

- Heat Recovery systems for utilization of waste heat from flue gases.

Safety Interlocks

- Automatic On/OFF of Fuel Burners corresponding to Low & High Temperature of Furnace.

- Automatic shutdown of the entire system in case of tripping of ID fan or Recirculation Pump.

- No Waste loading unless the temperature of Primary & secondary Furnace reaches desired temperatures.

- Real-time temperature logs and recording of alarms and other incidences to know the exact mode of operation.

- Venting of Exhaust gases from primary & secondary furnace in case of power failures or emergency shutdowns to prevent any accident or damage to the system.

To know more, please check MEPL.