BioEnergy Consult: Pyrolysis of Municipal Wastes

Pyrolysis is rapidly developing biomass thermal conversion technology and has been garnering much attention worldwide due to its high efficiency and good eco-friendly performance characteristics. Pyrolysis technology provides an opportunity for the conversion of municipal solid wastes, agricultural residues, scrap tires, non-recyclable plastics, etc into clean energy. It offers an attractive way of converting urban wastes into products that can be effectively used for the production of heat, electricity, and chemicals.

Pyrolysis of Municipal Wastes

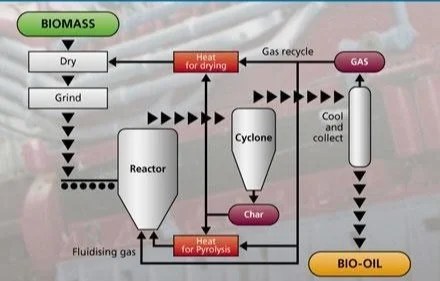

The pyrolysis process consists of both simultaneous and successive reactions when carbon-rich organic material is heated in a non-reactive atmosphere. Simply speaking, pyrolysis is the thermal degradation of organic materials in the absence of oxygen. Thermal decomposition of organic components in the waste stream starts at 350°C–550°C and goes up to 700°C–800°C in the absence of air/oxygen.

Pyrolysis of municipal wastes begins with mechanical preparation and separation of glass, metals and inert materials prior to processing the remaining waste in a pyrolysis reactor. The commonly used pyrolysis reactors are rotary kilns, rotary hearth furnaces, and fluidized bed furnaces. The process requires an external heat source to maintain the high temperature required.

Pyrolysis can be performed at a relatively small scale which may help in reducing transport and handling costs. In pyrolysis of MSW, heat transfer is a critical area as the process is endothermic, and sufficient heat transfer surface has to be provided to meet process heat requirements.

The main products obtained from the pyrolysis of municipal wastes are a high calorific value gas (synthesis gas or syngas), a biofuel (bio-oil or pyrolysis oil), and a solid residue (char). Depending on the final temperature, MSW pyrolysis will yield mainly solid residues at low temperatures, less than 4500C, when the heating rate is quite slow, and mainly gases at high temperatures, greater than 8000C, with rapid heating rates. At an intermediate temperature and under relatively high heating rates, the main product is a liquid fuel popularly known as bio-oil.

Wide Range of Products

Bio-oil is a dark brown liquid and can be upgraded to either engine fuel or through gasification processes to syngas and then biodiesel. Pyrolysis oil may also be used as liquid fuel for diesel engines and gas turbines to generate electricity.

Bio-oil is particularly attractive for co-firing because it can be relatively easy to handle and burn than solid fuel and is cheaper to transport and store. In addition, bio-oil is also a vital source for a wide range of organic compounds and specialty chemicals.

Syngas is a mixture of energy-rich gases (combustible constituents include carbon monoxide, hydrogen, methane, and a broad range of other VOCs). The net calorific value (NCV) of syngas is between 10 and 20MJ/Nm3. Syngas is cleaned to remove particulates, hydrocarbons, and soluble matter, and then combusted to generate electricity.

Diesel engines, gas turbines, steam turbines, and boilers can be used directly to generate electricity and heat in CHP systems using syngas and pyrolysis oil. Syngas may also be used as a basic chemical in the petrochemical and refining industries.

The solid residue from MSW pyrolysis, called char, is a combination of non-combustible materials and carbon. Char is almost pure carbon and can be used in the manufacture of activated carbon filtration media (for water treatment applications) or as an agricultural soil amendment.

To know more, please check BioEnergy Consult.