By Vidhya Sreenivasan

The Indian cement industry is the second-largest producer of cement globally. Dominated by around 30 prominent players, the Indian cement industry comprises around 210 large cement producing plants and 365 small ones. The industry continues to enjoy robust market demand through the pandemic situation, as India continues to be the second-largest global consumer of cement. In the financial year 2020, the Indian cement industry had a turnover of ₹64,000 crores. The Indian cement industry enjoys a reputation for being among the best in the world.

On the other hand, the cement industry is one of the most significant contributors to air pollution[1]. The cement industry contributes to around 7% of global carbon emissions. Particulate matter (PM) emissions from cement plants are very high, and cement is understood to be the most severe pollutant in the world. This article touches upon the kinds of pollution emitted by the cement industry and how these emissions can be effectively dealt with.

The Prosperity of The Indian Cement Industry

The cement industry enjoys a high level of stability among Indian industries. Thanks to government housing schemes, urbanization, and policies to renew and refurbish roads and other infrastructure, both production and consumption of cement remain high in India. The Union Budget 2021-22 has allocated a high budget for infrastructure. Further, India is naturally rich in limestone, one of the key ingredients of cement.

Due to multiple reasons, the potential for the cement industry’s uninterrupted growth is quite promising. One of the oldest and most significant industries, it has contributed as high as 0.10% to the GDP. Producing a metric ton of cement generates job opportunities for around 14 lakh people[4].

Further, with ESG regulations becoming increasingly mandatory for companies to enjoy a certain public image and trust, more companies are working towards their sustainability reports. Indeed, Indian cement industries enjoy a reputation for being green and having in place systems towards checking pollution.

Some of the sustainability practices followed by the Indian cement industry include:

-

Substituting clinkers with fly ash, which is readily available and reduces emissions and fuel consumed for producing clinkers.

-

Using electrostatic precipitators, etc., to check air pollution.

-

Using alternative fuel resources. To mention a case, UltraTech Cement aims to get 25% of its power requirements from green energy by the end of 20215.

-

Co-processing, i.e., using waste materials as fuel by burning them in the high temperature of the kilns. This also effectively disposes of solid waste.

Additionally, the government has made norms stricter for the cement industry, capping the emissions of PM to not more than 30 milligrams per cubic metre in March 2017. An official belonging to the cement industry complained then of the “limited availability of technology” that made it difficult for them to comply with the regulation enacted by the Union Ministry of Environment, Forest and Climate Change[8].

How Polluting is The Cement Industry?

Did you know that a single cluster of large-scale cement plants in a North Indian state is responsible for 5% of the world’s anthropogenic CO2 emissions[7]?

The effects of the cement industry’s pollution on life can be very severe. Below are some of the findings on its impact on humans and human-made systems:

1. Random tests conducted on workers in cement industries in Bengal and Tamilnadu have shown that 1/5th of the worker population is affected by diseases such as bronchitis, asthma, and obstructive respiratory disease, among others[2].

2. A recent study in Sri Lanka, which has ecological and geographical proximity with India, found that over 14% of the people living close to cement factories are afflicted with respiratory disorders[2].

3. In an interesting study conducted in the US, the economic benefits of reduced PM emissions from the American cement industry were estimated to range between 0.76 and 3.97 million USD annually[3]. The implications of such a finding in India, which produces three times the amount of cement produced by the US, are evident.

Evidently, stronger pollution control technology needs to be implemented to enjoy a wide range of benefits.

Where Does The Problem Arise?

For a lot of cement companies, emissions continue to be high, despite having installed pollution control systems. We come across news articles from time to time, citing cement firms paying heavy fines to the tune of tens of lakhs, if not higher6; or sometimes, even shutting plants for violating pollution norms. Shutting down a plant even for a month can seriously impact a company’s sales and overall efficiency.

The pollutants commonly emitted by cement plants are dust or particulate matter, NOx, SOx, carbon oxides, and methane, among others. Cement being the major contributor to air pollution, an approximate number of 4,90,000 annual deaths may be attributed to emissions from the cement industry. Further, emissions from cement factories pose a threat to the life of surrounding flora and fauna.

One of the major challenges faced by the cement industry is unaccounted or ‘fugitive’ emissions.

Fugitive emissions refer to the emission of pollutants that are ‘fugitive’ or escape from a source without being accounted for. Regular emissions from known sources are accounted for and hence easier to track and control. Fugitive emissions, on the other hand, are difficult to track since their source is unknown. Hence, they contribute to ambient air pollution in an untraceable way. The problem of fugitive emissions occurs during every stage of the cement manufacturing process and poses a huge challenge.

Conventionally, cement industry pollution control equipment includes electrostatic precipitators, baghouses, pulse jet filters, and industrial scrubbers. However, these have a limited and clearly defined area of coverage, and therefore, cannot treat fugitive emissions very effectively. The above-mentioned methods are energy-consuming, require regular maintenance, and are expensive, given their capacity of coverage. They are not very effective in treating ambient air pollution either.

Processes in Manufacturing Cement That Release Fugitive Emissions

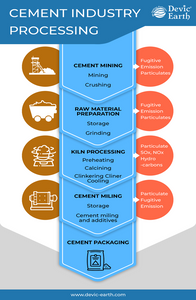

Manufacturing cement is a detailed process involving several steps. Fugitive emissions are released in each of these processes, as detailed in the infographic below.

-

Mining – As the raw material for cement is mined from limestone quarries, a variety of processes such as drilling, blasting, crushing, transporting, and stockpiling are involved, which result in the emissions of particulate matter and carbon dioxide.

-

Raw Material Preparing – The raw material is mixed and ground to consistency in processes that are either dry, wet, or semi-dry. In the processes of both grinding and further transporting to the kilns, fugitive emissions of particulate matter happen.

-

Kiln Processing – This process involves combusting in the kiln. The raw material is heated, and clinkers, or hard, spherical nodules are produced as a result. Kiln processing involves the following stages: drying or preheating, calcining, and clinker cooling. Calcination is the process of burning the raw mix at a high temperature so that clinkers are formed. These clinkers are later cooled by air blowers before being transported to the cement mill. Emissions at this stage are mainly in the form of gases such as carbon dioxide, SOx, NOx, carbon monoxide, and hydrocarbons. These are released both from the mixture that is being burned and treated and the fuel used for burning.

-

Cement Milling – This is the final stage of producing cement, where the clinkers are ground into a fine powder. Certain chemicals are added in order to set the cement. This stage is also called finish milling. The emissions released during this stage include particulate matter, SOx, and NOx.

-

Cement Packaging – This involves the dispatch and conveyance of cement. Particulate matter emissions happen significantly in this stage, during the loading, transport, unloading, and storage of cement from the warehouse to construction sites.

In addition to the above-mentioned emissions, VOCs are released during other industrial processes associated with these stages.

It is evident that the predominant fugitive emission is that of particulate matter.

The Solution – How Can The Problem of Fugitive Emissions in Cement Manufacturing be Tackled?

For arresting fugitive emissions, the only effective solution is pollution control equipment designed to address ambient air pollution, i.e., air pollution across large areas. Technology that addresses pockets of air is more or less purposeless. The technology should cover a significantly large area, addressing pollutants that are emitted from sources that cannot be accounted for.

Devic Earth’s Pure Skies is a breakthrough technology that does exactly this. It addresses very large areas, cleaning ambient air pollution, including fugitive and regular emissions. A clean sweep, it reduces air pollution by removing pollutants such as PM2.5, PM10, NOx, SOx, and others from the air. One unit of Pure Skies is sufficient to cover very large areas at an affordable cost per unit area. Pure Skies is highly effective, as discussed in the upcoming section on our use case at a leading cement plant in India.

The technology behind Pure Skies is based on pulsed Wi-Fi. Pulsed radio waves are spread across the area to be covered via base stations and extender units of Pure Skies. This operates in the normal Wi-Fi signal range and is completely safe. Further, it does not interfere with the activities of a manufacturing plant in any way. Our unique technology conglomerates particulate matter, PM2.5 and PM10 in the air, making them heavy and sink to the ground. Pure Skies only accelerates the natural process of dry deposition, whereby minute particles of dust settle in the ground.

A Use Case

Pure Skies was installed at one of India’s leading cement manufacturing plants to mitigate the problem of high, often unaccounted emissions. Despite having in place pollution control systems, the plant still faced high emission of pollutants, and associated risks such as opposition from neighboring communities, and also the administrative roadblocks in terms of closing the plant and/or being charged heavy fines.

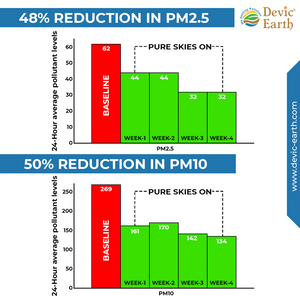

Within one month of installation, Pure Skies

i) Reduced PM2.5 levels by 48%

ii) Reduced PM10 levels by 50%

The plant benefitted from the immense drop in pollution levels, and enjoyed the security and enhanced performance enabled by Pure Skies.

Why is Pure Skies the best choice?

Compared to conventional air cleaning methods in industries, such as electrostatic precipitators, baghouses, scrubbers and filters, Pure Skies fares much higher, on several grounds. The previously mentioned methods have a very limited area of coverage: they can cover the size of a tennis court, or lesser. They are filter-based, and can clean small pockets of air. These are unfit to address ambient air pollution and fugitive emissions.

Pure Skies is a scalable and highly benefitting solution for the following reasons:

1. It covers extremely large areas.

One unit of Pure Skies can easily cover acres of a premise, at a very affordable cost per unit area. It has demonstrated a high rate of efficacy, bringing down air pollution by 33-90%.

2. It is affordable.

You can subscribe to Pure Skies and enjoy a large area coverage at the least cost per unit area.

3. Unlike most other air cleaners, Pure Skies does not require maintenance.

It is not filter-based, and therefore, avoids all the hassles and extra expenses that most other air cleaners demand. It is a silent, plug and play technology.

4. It leads to improved productivity and profitability.

Installing Pure Skies has restored a great deal of productivity by reducing sick leaves and increasing employee productivity. Customers who’ve installed Pure Skies have seen a 13% year-on-year reduction in their employees’ sick leave.

5. Monitor air quality in real-time.

Pure Skies comes with a third-party air quality monitor. It lets you visualize your air quality baseline, and then clearly note the reduction in levels of pollutants.

The World’s First Clean Air as A Service

Pure Skies is available for subscription, like most of today’s smart and user-friendly services. With a one-time activation fee, enjoy clean air always, with the flexibility to opt-out anytime. Avoid Capex investment; pay a monthly fee as you go.