Effluent Treatment Plan for Milk Processing Units

For the Milk Processing Industry, wastewater emanates from spillage of milk and products thereof, and from cleaning of equipment that has been in contact with milk products. The concentration and composition of the waste depend on the production programme, operating methods, and the design of the processing plant. Being organic in nature, the pollution load from the processes is quite high.

While Industry is continuously trying to adopt modern processes to reduce water consumption, we at EROS, are helping them to treat the polluted water generated by them and therefore minimizing the impact of water use.

Eros Envirotech (P) Ltd., is a Ludhiana (India) based environmental engineering company engaged in providing turnkey solutions for pollution control to the industry in textile/ yarn dyeing and other fields for over a decade now.

We provide comprehensive and reliable solutions to the industry within cost and time parameters. Further, our design and project execution skills help us to engage clients meaningfully to understand their requirements and deliver on that.

Processes Involving Generation of Effluent

For Milk Processing Industry, wastewater emanates from the following sources:

- Washing of Machines, Equipment and Storage or Transfer containers

- Washing of Production Areas

- Spillage etc

These type of effluent are generated in all types of Milk Processing Units including:

- Milk Processing

- Butter Milk / Sweetened Milk Production

- Paneer / Cheese Making

- Ice Cream Making

It is pertinent to mention here that neither the processes nor the type of product being made as listed above are an exhaustive list. They are indicative of the gamut of operations in which the industry is involved.

Characteristics of Untreated Waste Water

Typical characteristics of untreated wastewater are as below:

| Parameters | Concentration |

|---|---|

| Temperature | Ambient |

| pH | 7.5 – 8.0 |

| Oil & Grease* | 200 mgl |

| BOD | 1200 mgl |

| COD | 2500 mgl |

| TSS | 400 mgl |

| TDS | 800 mgl |

*Certain operations like Cheese Making will have higher Fat content (Whey) in their discharge. It may need additional treatment and has not been discussed in this document.

Characteristics of Treated Water

Treated Effluent will have characteristics as below:

| Parameters | Concentration |

|---|---|

| Temperature | Ambient |

| pH | 7.0 – 8.0 |

| Oil & Grease* | 10 mgl |

| BOD | 30 mgl |

| COD | 100 mgl |

| TSS | 100 mgl |

| TDS | 800 mgl |

Treatment Process

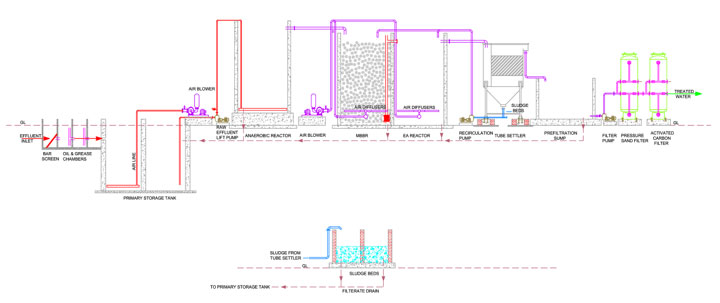

Waste Water passes through a Bar Screen & Oil & Grease Trap is stored in a two partitioned Equalisation cum Storage Sump. An Air Blower with an Aeration Grid is provided here to continuous agitation and mixing. From here it is lifted with the help of a Raw Effluent Lift Pump to an Anaerobic Reactor. This is a suspended growth type Bio-reactor where bio-mass develops and metabolises organic impurities in the absence of air. Required water re-circulation rates are maintained in the reactor through the feeding pump itself.

Waste Water is then fed to a State of the Art MBBR (Moving Bed Biological Reactor). Here Bacteria Culture develops on Random Floating Media. These micro-organisms derive their food from the organic impurities in water and air from an Air Blower which diffuses air in Fine Bubble Form at the bottom of the reactor through Membrane Diffusers. This is followed by a polishing EA Reactor (Extended Aeration) where the air is provided with the help of Air Blower and diffused through Diffusers to improve upon the results of the MBBR. This reduces the BOD Load of the Discharge significantly.

Water from here is fed to a Highly Efficient Tube Settler where finer suspended impurities, as well as dead organic matter from the MBBR, is settled and dumped to Sludge Drying Beds. Part of Sludge is recycled in the system using a Sludge Recycling Pump.

Water after Tube Settler is stored in Pre-filtration Sump and is pumped through a Filtration Pump to a Pressure Sand Filter and an Activated Carbon Filter. It removes very fine suspended particles in the Discharge Stream, as well as traces of any impurity or any odour or colour inherent in the stream. BOD and COD of water are further reduced during Filtration.

Treated Water is then fit for disposal into Municipal Sewers or for use in Irrigation & Plantation on Land.

Isometric view of Effluent Treatment Plant

To know more, please check Eros Envirotech.