With an eye toward a zero-carbon energy future, GE researchers are partnering with top chemists and engineers from UC Berkeley and the University of South Alabama. The team has been awarded a two-year, $2 million project through the U.S. Department of Energy (DOE) to develop a novel, potentially game-changing system for capturing carbon dioxide directly from the air. The DOE’s award is for $1.5 million, with a $500,000 cost-share from GE and its partners.

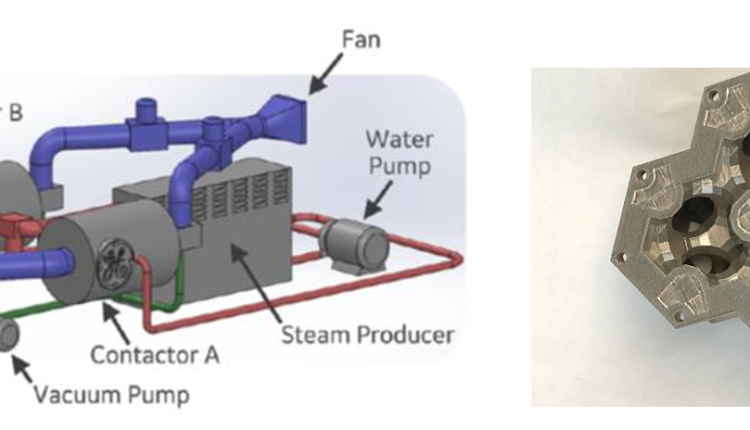

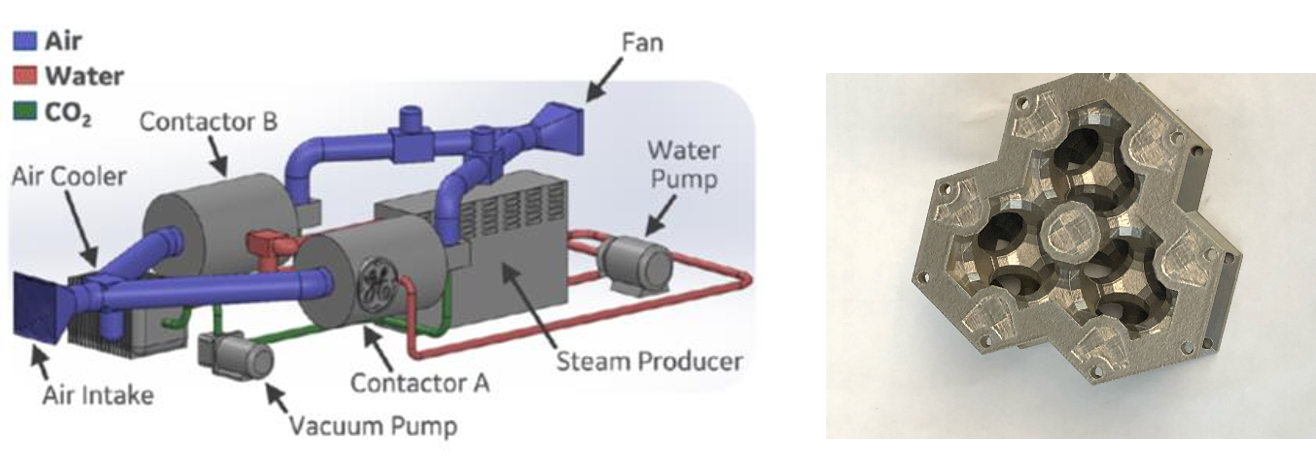

GE Research, with its University project partners, is developing a unique approach that involves pairing 3D-printed heat exchanger technology with innovative sorbent materials to create a system that effectively extracts carbon, in the form of carbon dioxide, from the air. This same team is employing a similar innovative approach to extract water from the air as part of an ongoing project with the Defense Advanced Research Projects Agency (DARPA) to provide potable clean water for troops in the field.

Caption: GE researchers are developing 3D-designed and printed heat exchangers (like the one seen at right) to integrate into its system for removing carbon dioxide. These heat exchangers will optimize temperature management to maximize the extraction of carbon dioxide with the sorbent-based material system.

“We’re combining GE’s extensive knowledge in materials, thermal management and 3D printing technologies with UC Berkeley’s world-class expertise in sorbent materials development and the University of South Alabama’s and sorption modeling and testing to design a novel system for removing carbon dioxide from the air,” said David Moore, the Principal Investigator and Technology Manager for Material Physics and Chemistry at GE Research. “Through this project, we’re aiming to demonstrate the feasibility of a system that could become a future large-scale, economical solution for widespread decarbonization of the energy sector.”

Moore explained that the GE Research team brings decades of technical and domain experience in materials innovation, process engineering and commercialization, heat exchanger and other thermal technology design and development for its power turbine and jet engine platforms, and rich expertise in 3D printing, or additive manufacturing technologies. GE has an additive business and is a top manufacturer of 3D metal printers. In addition, GE Research has a dedicated team of additive researchers supporting the design and development of 3D-printed parts for a variety of industrial products across GE’s business portfolio in energy, aviation, and healthcare.

The team from UC Berkeley, led by renowned Professor of Chemistry, Omar Yaghi, is a world-recognized leader in the development of sorbent materials that are capable of extracting targeted elements out of the air. “Since the first crystallization and proof of porosity of metal-organic frameworks in 1995 and 1998, respectively, we have been continually developing their chemistry and design on the atomic/molecular scale,” Yaghi said. “Teaming with GE on applying these materials in carbon dioxide capture is, therefore, a timely and most fortunate collaboration to address one of the most pressing problems facing our planet.”

While UC Berkeley will focus on the development and application of sorbent materials in the system, the team from the University of South Alabama, led by Prof. Grant Glover, will help inform the selection of the right materials for the system. “Metal-Organic Frameworks (MOFs) provide an exciting opportunity to design materials to separate gases,” Glover said. “With the opportunity to pair these insights with the GE team that has expertise in manufacturing and product development, the possibilities of what we can bring to CO2 capture are quite exciting.”

To know more, please check Schneider Electric.