Induction Melting Furnace

About Induction Melting Furnace

Induction Melting Furnace is a major steel-producing technology using scrap & sponge iron (Directly Reduced Iron) as the main raw material. This technology contributes significant steel-making capacity in the secondary steel sector in India.

It has some distinct advantages:

- Low Project Capital Cost

- Low Energy Cost

- Consumes steel scrap which is a major solid waste

- Environment Friendly, as it produces lower emission than Primary Blast Furnace

- Uses clean fuel i.e. electrical power

- Can be set up near-source which saves transportation cost of raw material as well as finished goods.

Manufacturing Process

The induction Furnace Process includes the melting of various types of steel scrap in a pot. The energy required for the melting process is provided by electrical induction. The feeding of raw material in the induction furnace is on an intermittent basis. As one charge of scrap melts, slag is removed from the molten metal and certain alloys are added to achieve the desired grade of steel. Molten metal is then poured into refractory lined buckets from where it is further poured in different sizes molds to get the desired size of steel cast. Ingot/Billet is allowed to cool down and then the product is separated from the molds.

Flue gases are generated during the melting of scrap. The characteristics and volume of these gases mainly depend upon the type of scrap used in the furnace, i.e. with the degree of contamination in the Scrap. These flue gases need proper treatment for the removal of dust particles/gases before being discharged into the atmosphere.

Air Pollution

Steel scrap comes from various sources and generally has contaminants/coating etc on it. When this scrap is heated contamination/coating etc disintegrates from steel and comes out either as slag or becomes airborne, thus causing air pollution. The major source of Air Pollution is:

- Dust & Dirt

- Rust

- Oil & Grease

- Paint

- Galvanized Iron

- PVC Coated Steel

Capacity calculation of required equipment

The volumetric capacity of Air Pollution cannot be judged as such, but fair engineering estimation can be made with input data like:

- Furnace Capacity

- Power Rating in kWh

- Detailed Dimensions of Furnace

- Air Cooler Arrangement for workers at Furnace Platform

Selection of Technology for Equipment

Selection of Technology for Equipment in an Air Pollution Control System in case of a Steel Re-rolling Mill depends upon the fuel to be used:

- Scrubber based System for Oil / Gas Fired Furnaces

- Cyclone and Scrubber based System for Coal-Fired Furnaces

Air Pollution Control System for Coal-Fired Steel Re-rolling Mills

The Working of APCS for Steel Re-rolling Mill (Coal Fired)

About the system:

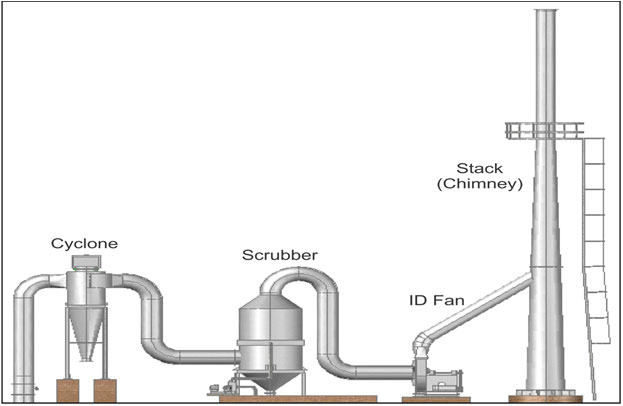

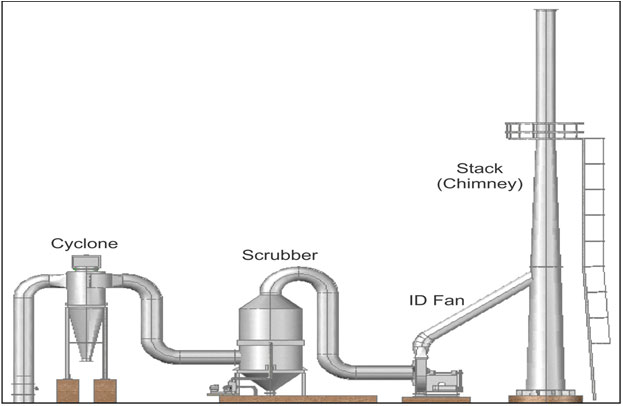

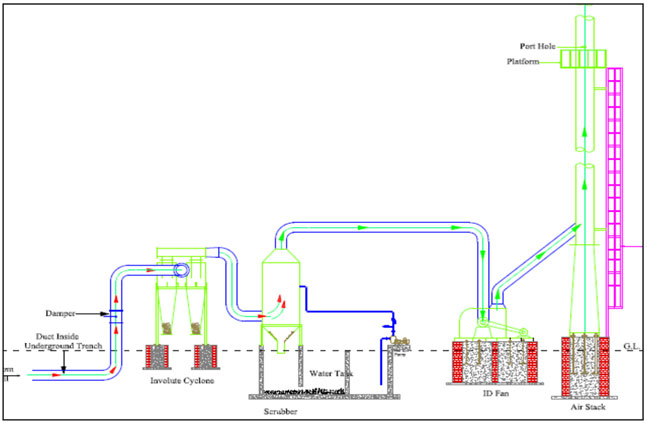

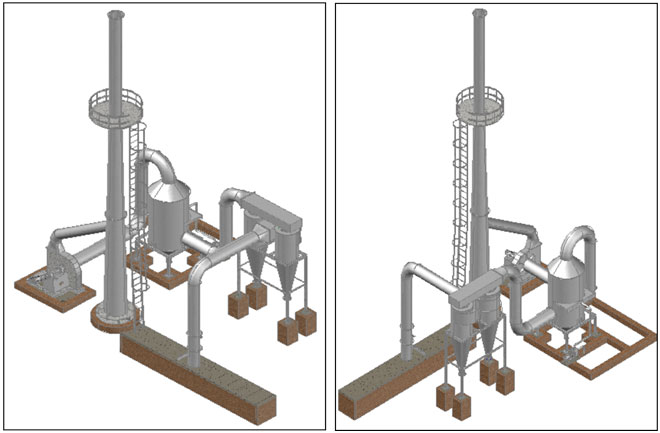

Air Pollution Control System for Steel Re-Rolling Mills (Coal Fired) is a Wet Type System. It consists of a high-efficiency Cyclone followed by a Perforated Tray Type Wet Scrubber and a set of ID Fan and Stack.

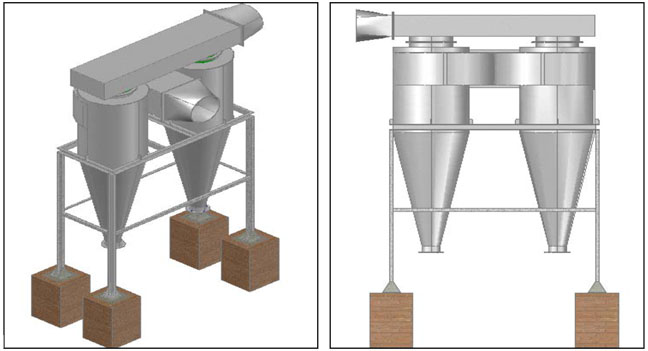

Involute Cyclone

It is provided to capture the medium size particles from the furnace. The mechanism of the device is based on centrifugal forces entering in a tangential inlet cyclone. The medium size particles are arrested in the cyclone so that the efficiency of the scrubber concerning fine particles increases.

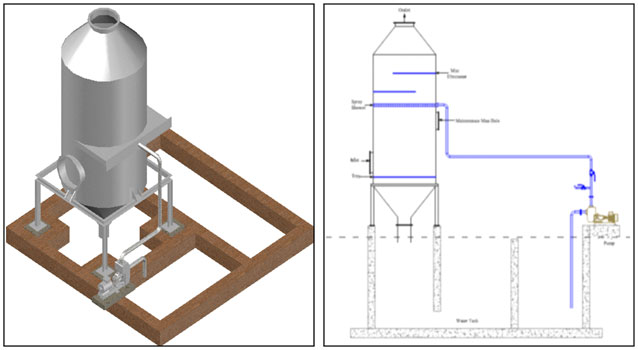

Scrubber

The unit has been provided with a Wet Scrubber. It is a perforated plate-type single-stage scrubber. Gases enter the scrubber from the side of the column and are showered with a water spray as they move up through the tray and column, forcing them to shed the fine particles they are carrying. Further, they pass through a mist eliminator to ensure that no moisture is carried over from the scrubber. Water carrying dust particles is settled at the water tank below, which is partitioned in a manner to separate suspended particles while the water is recycled.

- The Scrubber is in Stainless Steel construction to resist corrosion.

- pH balancing details are provided to maintain the pH of feed water for the long life of the equipment.

- Maintenance manholes are provided for trouble-free operations of the Scrubber.

- Efficient Mist Eliminators are provided so that no moisture is carried over.

- Three partitioned tanks are suggested for the settling of suspended particles in the recycled water.

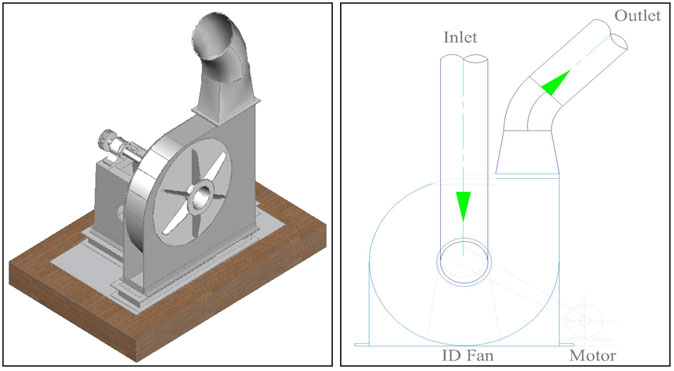

ID Fan

They have been provided for creating an adequate negative pressure in the system for efficient suction of gases.

- The ID FAN is statically and dynamically balanced.

- The ID fan is provided with adequate static pressure for such types of devices.

- The fan volume is adequate to provide the required dynamic pressure at the suction point.

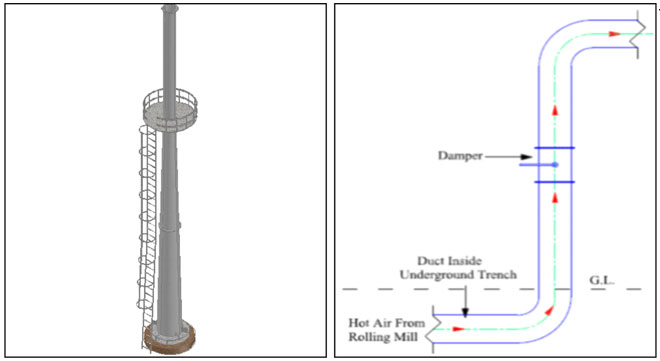

Air Stack

- It is provided to release the treated gases into the atmosphere through an adequate chimney.

- The air stack is provided with an aerodynamic bottom part to enable easy flue gas entry and for structural strength.

Ducting

Ducting and Bends are provided in the system for the conveyance of gases at appropriate velocities and also to reduce the temperature by natural convection. An adequate length and size of ducting are necessary for the proper conveyance of the gases at minimum pressure drop. The bends provided should be aerodynamic in shape so that there will be minimum pressure drop and no dust build-up during operation. The main feature are

- All bends and fittings are aerodynamic resulting in min. pressure loss and min. dust accumulation.

- Provided with manual damper for adjusting suction draft of the ID Fan if required.

Isometric View of Air Pollution Control System

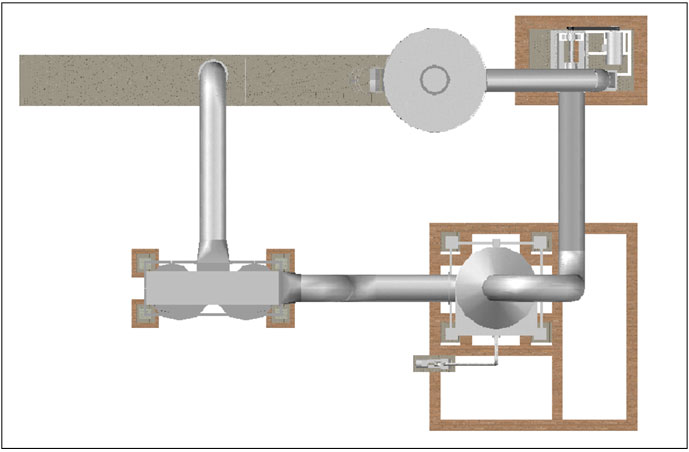

Plan View of Air Pollution Control System

To know more, please check Eros Envirotech.