Industrial Boilers For Enhancing Production Processes

Ever thought of enhancing your production efficacy without wasting money on electric energy? Did you know Industrial Boilers are powering many industries? Did you know Industrial Boilers are of various types and have different utilities? If not, here’s everything that you must understand about Industrial Boilers.

Heat is vital for life. Without it, we cannot sustain. From cooking to styling your hair, we need heat for almost everything. Our pressure cookers can explain the basic concept of steam boilers where steam is pressurized and used for cooking. Heat energy also reduces the reliance on fossil fuels like petrol, diesel, and more.

For centuries we have been using boilers in various forms to heat water or to produce steam. Household boilers and Industrial boilers though have different purposes, but the operational aspect is similar. Good Industrial Boilers are known for their energy efficiency and massive heat production that has the capability of running your production processes. From steam-powered locomotives to external combustion engines to power plants, for various purposes, industrial boilers are used.

The importance of Industrial Boilers is not unknown to manufacturing companies. They use industrial boilers for their many advantages; one of them is saving the cost of using electric energy for the entire process. Electric power becomes extremely expensive if used on a large scale, but Industrial Boilers help in keeping the extra expense in check. Boilers offer maximum efficiency and minimum menace like fewer hassles of handling and depending on electric energy.

In today’s time, efficient boiler technology is way more important than before. Heat energy will also improve equipment efficiency. Many industries are now using pressurized steam to run machines. It is not only efficient in enhancing your production but also is environment friendly in many ways.

First, it saves the companies from using gallons of electric energy which is expensive and harmful, according to an article published in 2015. Industries wasted three billion units of power. Imagine what the number for the amount of energy that was consumed would be! Appalling! Isn’t it? Here are the latest statistics of power consumption in 2020

The fuel used for the boilers is often natural gases and various other fossil fuels, coal, and more. Thus, it is crucial to choose the right boiler that does not waste the heat produced, ensuring more delivery than other sources of energy.

Some of the best boiler manufacturers, Thermax, for example, offers waste heat recovery solutions as well. Thermax ensures that all the heat that usually is lost as exhaust gas is utilized to its maximum potential. Advance designs and constant innovations help in bringing out the best in the boilers.

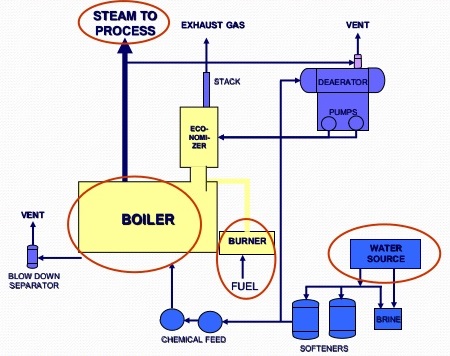

Necessary Parts of an Industrial Boiler:

Burner: The burner is the starter of the combustion reaction inside the boiler. There is a mechanism that sends the message to start the process of producing heat. A nozzle in the burner that turns the fuel pumped from the fuel source ignites it to create the combustion.

Combustion Chamber: The combustion chambers are made of cast iron and can have a temperature of several hundred degrees in minutes. It burns the fuel and generates heat which is transferred to the heat exchanger.

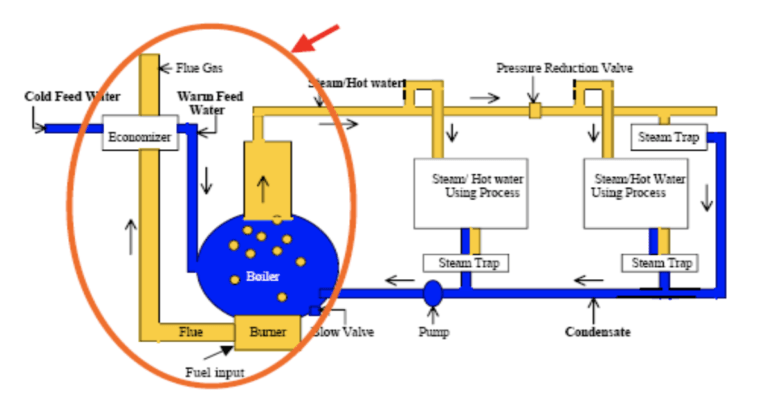

Heat Exchanger: Also called the economizer, it is responsible for increasing the efficiency of the boiler. The heat exchanger is placed before the air heater in the fuel gas path.

Steam Drum and Mud Drum: The steam drum collects the steam while the mud drum is placed beneath the steam drum and collects the solid which is removed periodically.

Fuel Sources used in boilers

From coal, kerosene to natural gases, the fuel can be of various types.

How does Industrial Boiler work?

Industrial Boilers are water-containing vessels that generate heat with the help of a fuel source. It is then transferred to various tubes connecting to the various industrial equipment. The steam energy is used for running the machinery, giving industries a cost-effective way of powering their production.

Creative Copy: Basic Functioning of Industrial Boiler

The way the boilers work is not as complex one would think. It is a mix of basic science and the latest innovations. Separate parts of the system are placed at different points.

The heat source and the water vessels are placed in different compartments. The metal rods that connect to the water vessel and then the heat helps in steam production. The steam is then collected in a dome to condense it before releasing it from the boiler. This increases the pressure, and the energy produced helps in powering your production processes.

Often for safety purposes, boilers come with a safety valve to ensure zero mishaps because of the increased pressure. There are different types of boilers, depending on the purpose of use. We will get into the details of the classifications as we go further in the article.

Boiler Care For Longevity And Better Performance

Here are a few things that one should always take care of to increase the lifespan of boilers.

- General safety checks at regular intervals are crucial for maintaining the boilers.

- Boiler temperature should be perfect as overheating can be a cause of the boiler’s breakdown.

- Avoid inefficiency by keeping a tab on the fuel levels, circulations, and pressure.

- A boiler should always have smoke detectors and alarms for low fuel and pressure for safer functioning.

- The Chimneys, vents, and outlets must be cleaned for better productivity of the boilers.

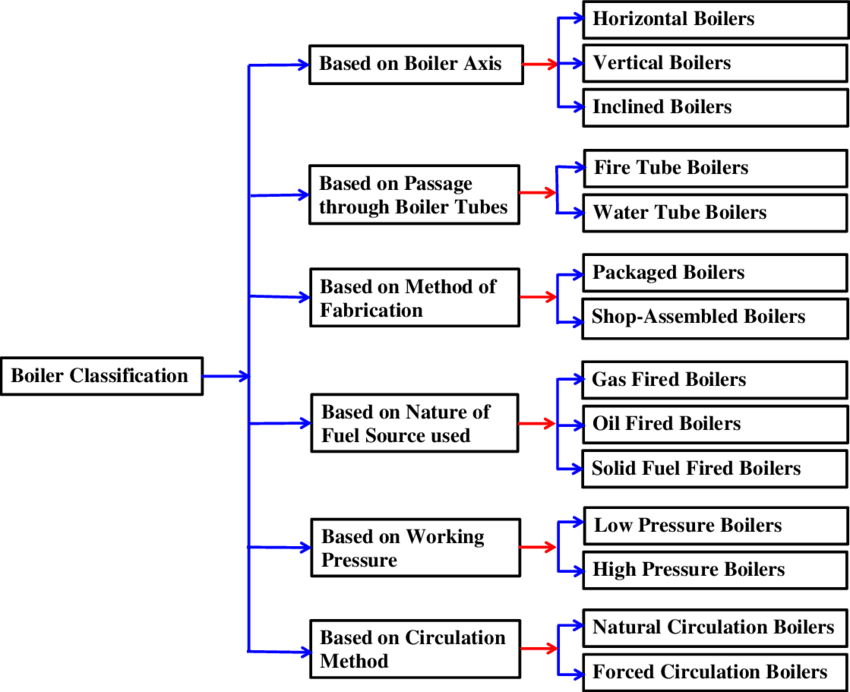

Types of Boilers:

The type of boiler you need will depend on your production requirements. Different types of boilers serve different purposes. The classifications are based on the amount of pressure it can create, the capacity to hold the fuel and water, and the type of fuel one will be using.

Creative Copy: Boiler Classification

Fire Tube Boiler

Fire Tube Boilers are used widely in small and medium-sized industries. They are factory-made and come with pumps and control systems, all set to start operations as soon as connected to a fuel and water supply. They are often called the packaged boilers. These kinds of boilers are befitting for low to medium pressure steam requirements. Here, the combustion gases flow outside the water pipes.

They also have the capacity to produce steam with up to 2200 horsepower pressure but comes with a tremendous risk of explosion. It might be a little expensive for companies that do not need steam energy at all times.

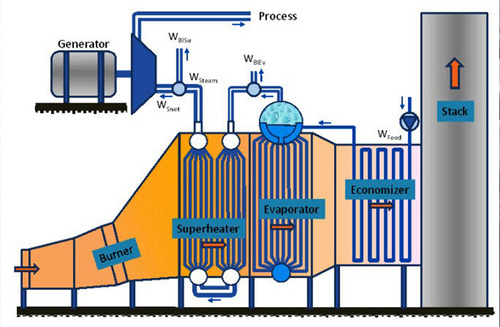

Water Tube Boiler

The Water Tube Boiler is multifaceted. They are significantly different from the fire tube boilers. The two types differ in the ways they function. Water Tube boilers are usually used in large manufacturing factories where there is a need for high-pressure requirements. There is a circulation of water between the mud and the steam drum, ensuring more control over the circulation by density differences.

They are perfect if you often need to change the steam quantity because of their lower water content. The water tube boilers are often built on sites and are usually not available in a packaged unit.

Electric Boiler

The most popular boiler type. It is incredibly efficient and environmentally friendly as it does not require any kind of fossil fuel and hence leaves a smaller carbon footprint. The best part is unlike other boilers; there are no exhaust fumes. Rural users use them widely as the installation cost is lower, less noisy, and requires less space than the others as well.

Though it looks like it is the most advantageous, it has its cons as well. It runs on electricity and involves heavy electricity consumption. Electric energy is not at all cost-effective.

Condensing Boiler

Condensing boilers are different and work differently. They use natural gases and two heat exchangers, making it the most efficient boiler. They extract heat from the exhaust or waste gases. This helps in reducing wastage. They are capable of achieving 98% thermal efficiency and are now replacing other boilers for central heating.

Many HVAC experts are of the opinion that this is the most sustainable boiler as its two heat exchangers help in the reduction of wastage and expenditure.

Oil Boiler

The efficiency of oil-fired boilers is usually 86% while oil condensing boilers are 90% or more efficient. The fuel used here is not natural gas but oil. The oil is ignited in the combustion chamber, and then the heat exchanger heats the cold water. It is usually used in the household to get warm water in showers, taps, or radiators.

Natural Gas Boiler

Natural Gas Boilers, as the name suggests, use natural gas as their fuel. A temperature gauge regulates it, and a thermoelectric device is used to reduce fuel wastage. The gas lights up the pilot which heats the coils in the boiler. Rural areas use propane gas most of the time.

It is essential to understand what your needs are, and this classification might be of help. It is always advisable to have a detailed discussion with experts from boiler manufacturers like Thermax or others. This will ensure you save your money and get the right one. Too small or too big, what type of fuels and more of such information you must always attain first before making a purchase decision.