Process Water for one of the Middle East’s Largest Industrial Developments, Sadara Chemical

The Facility

Sadara Chemical is a joint venture between The Dow Chemical Company, a world leader in science and technology, and Saudi Aramco, one of the world’s leading energy suppliers. Located in Jubail, Saudi Arabia, Ras Tanura Integrated Project (RTIP), once completed, will be the largest petrochemical facility ever constructed in one phase. RTIP is a world-scale integrated chemical complex, built to produce more than 3 million tons per year of value-added chemical and plastics products:

• Amines

• Glycol Ethers

• Isocyanates

• Polyether Polyols

• Polyethylene

• Polyolefin Elastomers

• Propylene Glycol

Project Overview

Aquatech was selected by Dow Chemical to manufacture the ion exchange and condensate polishing systems essential to operations. Two important drivers of this project were ease of installation and scheduling. Suppliers were tasked with manufacturing to a high specification while developing systems that were simple to install. Project milestones were critical as the multiple processing units were assembled on site. Aquatech’s Global Sourcing program provided the manufacturing muscle and flexibility required for meeting the critical project timeframes. Construction work on the project has already started and is scheduled to be completed by early 2015. Production from the first units is expected to begin in the second half of 2015; all units are expected to be running by 2016. The fully integrated complex is planned to consist of 26 chemical manufacturing units. Aquatech’s treatment processes will supply demineralized water for high-quality boiler makeup and condensate polishing.

Scope of Service

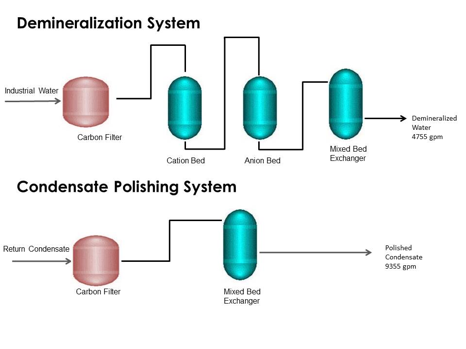

The Demineralization System consists of Activated Carbon Filters followed by UPCORE™ Cation Exchangers, UPCORE™ Anion Exchangers, and Polishing Mixed Bed Exchangers. The system produces 4755 GPM of Demineralized water from Industrial water. Condensate Polishing System consists of Activated Carbon Filters followed by Mixed Bed Polishers. The system treats Plant Return Condensate to produce 9355 GPM of Polished Condensate. Both systems also include dedicated Acid and Caustic Regeneration skids. A common Neutralization system including tanks and pump skid is provided to neutralize the regeneration wastewater prior to the site outfall unit.

Design Water Analysis

Process Flow Diagram